Exhibitor News

S.M TECH is exclusive agenet of China's largest robot company "BORUNTE" and 50-year-old dehumidifier company in Italy " NEWOMP". We are pleasure to participate in Ko-plas 2023 show.

We will present with main products such as BORUNTE Multi-axis robots, Traversing robots, NEWOMAP Honeycomb dehumidifiers and Gravimetric Blenders.

1.Multi-axis robot (BRTIR-1510)

1.Multi axis robots (BRTIR Series) -Robots with rotation joints, usually four or six axes robots are used. It is used in various industrial field such as loadings, transportings, weldings, packings, and assembly . The loading ability that can hold products is 5kg to 300kg, have extensive range of robots. and BORUNTE Robots are operated as open source not same as other robots, there is not charged of additional program cost. Manipulators just Need to train to sufficent manipulation to use robots.

2. Traversing robots (BRTR09WDS5PC)

2.Traversing robots (BRTR and BRTNG series) - Consist of 3-axis or 5-axis robots, also known as coordinate robots due to X Y Z each axis movement. It is mainly mounted on an injection molding machine(I.M.M) and used to take out products from the mold. There are varieties of product line ups that configured to its ranges of 50Ton-4000Ton of I.M.M. For the most important expandable part of product release, fixture and sucker line are composed of 7 lines, so it is also used for various take-out operations. As above, It adopts an open source program, so manipulators can easily apply difficult operations such as inserting and cap folding operations without any extra cost.

3. Honeycomb Dehumidifier (WD Series)

3.Honeycomb Dehumidifier,(WD series, Rotor Honeycomb dryers) - Used to remove moisture from plastic pellets. It is designed to compact size to less than 1/10 capacity of existing heaters can be complementary heat loss by reducing inefficient parts due to the use of high-capacity heaters, which were disadvantages of existing dryers and dehumidifiers. In addition, it is a small dehumidifier No need to use any extra machines such as the use of Compress air like an air dehumidifier, thereby preventing frequent failures. The cooling method is also air-cooled rather than water-cooled, allowing simple installation and maintenance.

4. Gravimetric Blender (DG mix Series)

4.Gravimetric Blenders (DGmix series) - There are various methods of mixing pellets, but this is to compensate origin problem such as uneven mixing, material separation during mixing, and the need for workers resources to input material on time . When the users touch buttons to the mixing ratio such as pellet and master batch into the program, it is automatically put into the mixing and injection machine or extrusion machine. It is a mixing method of measuring weight by material in a minimum batch unit (400g), and a small amount of weight measurement is mixed to ensure quantitative supply and uniform mixing.

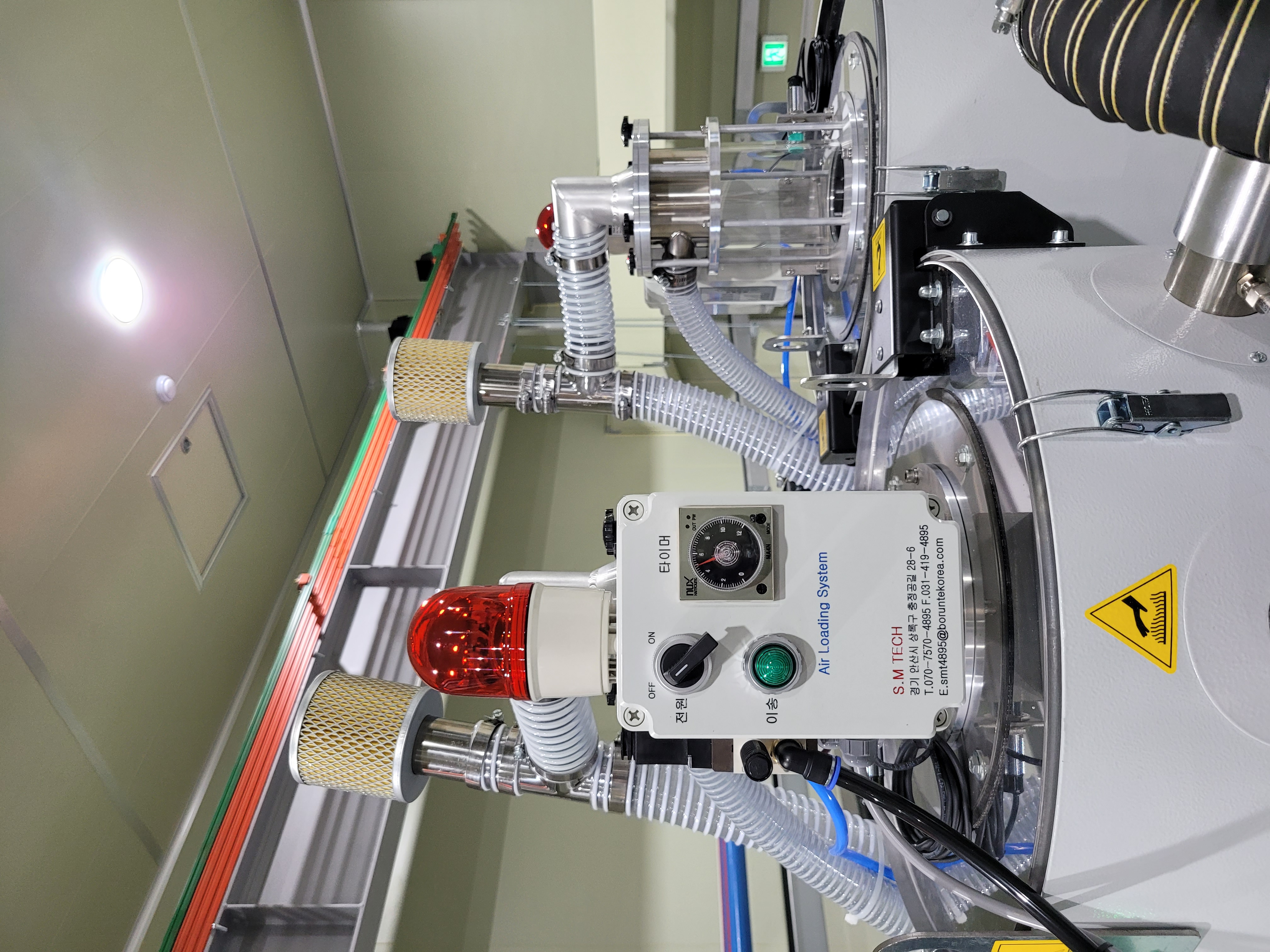

5. Air Loader (SMAL -10)

5.Air Loader (SMAL Series) - Used primarily for supplying material to the dryer or dehumidifier. Before, large equipment was required in a blower method, which was difficult to manage due to large costs and large space charges, but this Air loader equipment is so simple and compact to transfer pellets using air pressure using a factory utility (compressor). The product structure is that can be used after simply mounting it on a dryer.